Challenge

Finding a more effective, precise method to simulate the complex configurations and multibody dynamics of leaf spring suspensions has always been a significant hurdle in automotive engineering. Traditional methods proved to be laborious, intricate, and resource-heavy, making it tough to adapt suspension designs specifically for different vehicle models.

Solution

We developed a multibody dynamics modeling tool utilizing the SIMULIA Simpack solution, with valuable assistance from the Dassault Systèmes SIMULIA team.

Results

- Significantly improved efficiency – simulations that once took a full day can now be completed within an hour

- Rapid, reliable simulation outcomes thanks to Simpack's powerful solver

- Increased confidence in driving future automotive innovations

Some of the best ideas come from the past, but applying them to modern designs isn't always straightforward. Consider the leaf spring, a suspension component that dates back to 17th-century France and is still widely used today.

"Leaf springs are an ancient technology, yet they're incredibly cost-effective and deliver excellent suspension performance," said Ameya Apte, a vehicle dynamics and load simulation engineer at General Motors (GM).

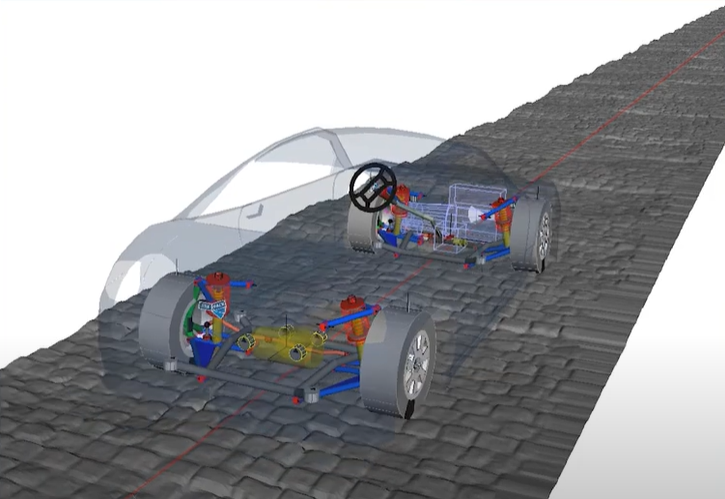

Leaf springs are essentially long, flat steel strips curved into arcs and stacked together. Sometimes multiple layers are added, each with varying numbers and shapes of leaves. This opens up countless configuration options.

"Different configurations of leaf springs offer distinct suspension characteristics for a vehicle," Apte explained. "A smaller vehicle would require a smaller leaf pack with fewer leaves, whereas a larger vehicle usually needs a bigger pack with more leaves. Primarily, the load carried by the rear axle determines the leaf design, depending on the desired ride quality and handling of the vehicle."

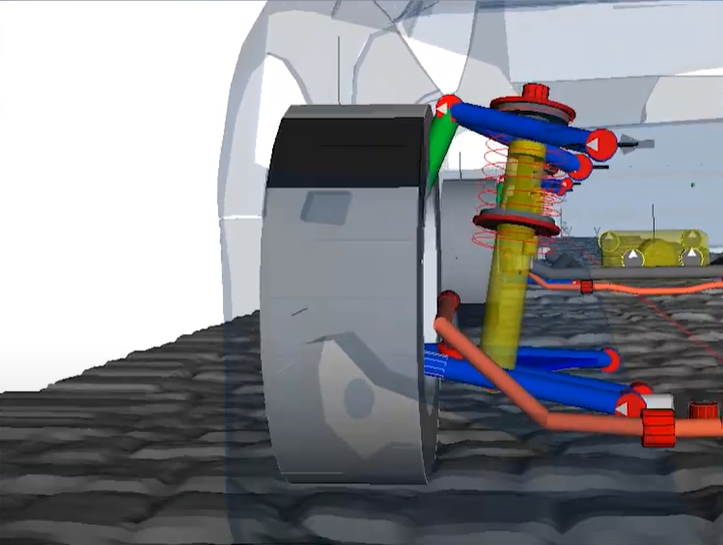

Simulation plays a crucial role in comprehensively analyzing how the leaves of each spring interact with each other.

"When examining internal stresses within a leaf, it's nearly impossible to do so through testing, but simulation makes it feasible," Apte stated. "Similarly, measuring the force between two leaves involves inserting a load transducer, but this also alters the model itself."

However, incorporating these multibody dynamics into simulations from a modeling standpoint was a complex and resource-intensive task. As a result, creating custom leaf springs for each vehicle program often proved time-consuming, prone to errors, and difficult to standardize as a process.

"Even though leaf springs have existed for hundreds of years, many believe they are easy to model, which is far from the truth," Apte remarked. "One challenge with leaf springs is that the leaves articulate with the suspension, requiring friction modeling between them. Additionally, the bushings connecting the chassis to the leaf springs possess frequency-dependent properties that must also be accounted for."

Automakers typically employ finite element analysis tools to model and simulate the intricate geometries, materials, and physics involved in vehicle design. For GM's leaf springs, Apte sought a multibody dynamics tool that would facilitate more efficient modeling of these complex systems. His team utilized SIMULIA technology to build the required tool.

"This tool enables us to produce standardized, custom-designed leaf springs for various applications," Apte noted. "Users simply input the parameters they desire for the spring—such as the number of leaves in a pack, their distribution across primary, secondary, and auxiliary packs, their shapes, tapering, and so on. Based on this information, the tool generates a model that predicts vehicle dynamics performance and loads."

Two critical factors contributed to the tool's success. First was the extensive support provided by SIMULIA's technical, backend, and R&D teams. Second was SIMULIA Simpack—a technology for developing and simulating high-fidelity multibody systems.

Apte was especially impressed with Simpack's solver, which outperformed other tools he had worked with.

"With Simpack, you rarely need to adjust solver parameters to get a model running," Apte explained. "You might tweak settings to optimize runtime or enhance accuracy in certain parts of the simulation, but generally, you don’t need to modify them just to run a model. That robust solver is invaluable because it lets us examine results, understand the underlying physics, and then pass the model along to our design engineers."

In addition to enabling faster leaf spring simulations, the tool also provides accurate results, allowing Apte and his team to simulate with confidence. "If a simulation for leaf springs takes a full day using FEA tools, Simpack can complete it in under an hour," Apte mentioned.

Looking forward, Apte believes the solver in this tool will remain relevant as the industry evolves and new technologies emerge.

"I think current physics solvers will be enhanced, not replaced, by disruptive technologies like AI and blockchain," Apte said. "The time it takes to bring a new vehicle to market has decreased significantly over the decades, and we see potential to reduce it further with new tools. In the long term, mastering these tools and envisioning how to combine them to create optimal applications will be a major part of our work."

Curious about the latest developments in simulation? Seeking advice and best practices? Want to discuss simulation with fellow users and Dassault Systèmes experts? The SIMULIA Community is the ideal platform to access the latest resources for SIMULIA software and collaborate with others. As the key to unlocking innovative thinking and knowledge sharing, the SIMULIA Community offers the tools you need to expand your expertise, anytime and anywhere.

Changshu Enzyme Biotechnology Co., Ltd. , https://www.nmnglutathione.com