Beneath the ocean's vast expanse lies a hidden treasure trove of oil and gas reserves, patiently waiting to be harnessed. Extracting these precious resources from the ocean floor demands ingenuity, cutting-edge tech, and an unwavering dedication to safety.

Offshore oil rigs, often referred to as oil platforms, play a pivotal role in this process. These colossal industrial structures rise above the waves, standing tall against the relentless forces of nature. From the first offshore rig constructed in the 1940s to the modern-day giants, these marvels of engineering have transformed how we access the vital resources powering our world, from heating our homes to fueling our vehicles and countless other items we use daily.

In this comprehensive guide, we’ll explore everything you need to know about offshore oil rigs, from what they are and how they function to their construction and the vital safety measures taken on these isolated platforms.

Let’s dive in!

---

What exactly is an offshore oil rig, and how does it differ from an oil platform? An offshore oil rig is typically a mobile structure used primarily for temporary operations, often in shallower waters. It’s designed to explore or extract smaller oil deposits. Jack-up rigs, a specific type, showcase this mobility—they can be moved by barges, lowered onto the seabed using long legs for stability, and then relocated after completing the task.

In contrast, an oil platform is a massive, permanent structure anchored to the ocean floor. These platforms are built for long-term operations in areas with abundant oil reserves, resembling small islands in the sea. They usually consist of three main parts: a sturdy jacket acting as legs, a spacious deck for equipment and operations, and modules housing everything from drilling machinery to crew living quarters.

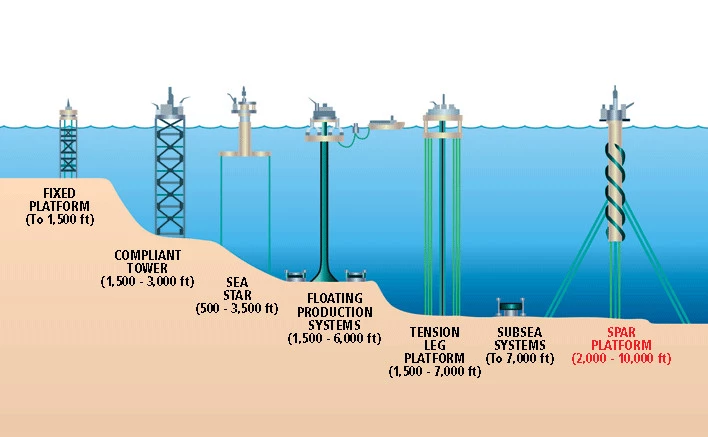

Examples include compliant towers with flexible support structures, SPAR platforms with a cylindrical design, and tension-leg platforms tethered to the seabed for added stability.

---

So, how does an offshore oil rig actually work? The process of extracting oil from offshore reserves is complex and requires a deep understanding of geology, engineering, and safety protocols. Let’s break down the intricate workings of offshore oil rigs, from initial exploration to production and transportation.

Check out the video below for a visual explanation of how offshore oil rigs work:

The journey begins with exploration, where companies aim to identify potential oil reserves beneath the ocean floor. Sophisticated technology is employed to survey the seabed. Sound waves emitted from devices equipped with compressed air penetrate the water, bounce off the seabed, and are captured by hydrophones. Scientists analyze this data to pinpoint areas rich in oil and gas deposits.

However, before drilling can start, companies must secure leasing rights from relevant authorities. In the U.S., the Submerged Lands Act (SLA) and the Outer Continental Shelf Lands Act (OCSLA) govern offshore lands. Additionally, companies need permits from regulatory bodies like the Bureau of Safety and Environmental Enforcement (BSEE) to comply with environmental and safety standards.

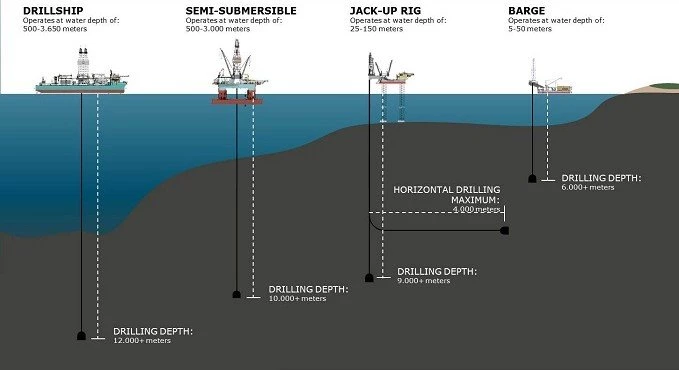

Once permissions are in place, oil and gas companies move to the next phase: drilling exploratory wells to confirm the presence of oil and assess its commercial viability. This is done using specialized drilling equipment called Mobile Offshore Drilling Units (MODUs), designed for various water depths and drilling conditions.

Different types of MODUs include drilling barges, submersible rigs, jack-up rigs, semi-submersible rigs, and drill ships. Each has unique capabilities, from operating in calm, shallow waters to deep-sea drilling at incredible depths.

These MODUs are equipped with specialized drilling tools, including a riser, drill string, blowout preventer (BOP), and casing strings. The riser connects the rig's deck to the seabed, providing a pathway for drilling operations. Metal casings are inserted into the wellbore to stabilize the formation, sealed with elements like O-rings to maintain integrity.

If hydrocarbons are discovered during drilling, the well undergoes testing to assess reservoir properties such as pressure, flow rate, and fluid composition. Depending on the results, the well may be temporarily suspended or permanently plugged and abandoned if it’s not commercially viable.

---

When commercially viable oil wells enter the production phase, hydrocarbons are extracted, processed, and transported to shore. The choice of production platform depends on factors like water depth, well depth, reservoir characteristics, and environmental considerations.

Fixed platforms are traditional structures anchored to the seabed, ideal for shallow to moderate depths. Compliant towers are tall, resilient structures designed to withstand harsh conditions like hurricanes and rogue waves. Tension Leg Platforms (TLPs) and Mini-TLPs are tethered to the seabed with vertical movement capability, suitable for deep waters.

Floating production systems like FPSOs and FPUs are used in ultra-deepwater environments where fixed platforms are impractical. Subsea systems extract hydrocarbons and transport them via pipelines in extremely deep waters. SPAR platforms, with cylindrical designs, are anchored to the seabed with tethers and anchors, suitable for depths up to 10,000 feet.

Production platforms are equipped with facilities for drilling, processing, and storing hydrocarbons. They house essential equipment like drilling rigs, production risers, wellheads, separators, pumps, and storage tanks. Personnel live and work onboard for weeks or months at a time.

Transportation of extracted hydrocarbons relies on extensive pipeline networks. Infield pipelines connect subsea wells to production platforms, while export pipelines transport processed oil or gas to shore. Shuttle tankers may also be employed to transport crude oil from FPSOs to onshore refineries.

---

Building an offshore oil rig is no small feat. It’s a monumental task that demands meticulous planning, advanced technology, and skilled labor. Let’s explore the comprehensive process of constructing these massive structures.

Check out the video below for a closer look at how offshore oil rigs are built:

The journey starts with a meticulous design phase. Years of effort go into creating a blueprint for the rig, considering the harsh realities of its environment. Engineering challenges, environmental factors, target resources, and 3D modeling all play a crucial role in the design process.

Next comes the fabrication stage, where various components of the rig are built. Specialized locations house fabrication facilities equipped with cutting-edge technologies and materials. Once completed, these components are transported to the designated location for assembly—a logistical marvel requiring a specialized fleet of ships and barges.

Installation follows, where the components are carefully positioned and connected using cranes, welding equipment, and other specialized tools. This process can take several months and is vital for ensuring the rig’s safety and functionality.

Before the rig can begin operations, a series of rigorous tests are conducted, including pressure tests, flow tests, and electrical tests. Owning a standard onshore drilling rig can cost between $14 million and $25 million, but offshore rigs are an entirely different story. Their construction costs start at $20 million and can soar to a staggering $1 billion, with drillships often topping the charts.

---

Despite the economic benefits, offshore oil rigs present significant safety hazards. Workers face constant risks from moving equipment, falling objects, and high-pressure lines. Strict safety protocols and proper equipment maintenance are crucial for mitigating these risks.

Struck-by/Caught-in/Caught-between hazards account for a staggering 60% of oil rig fatalities. Moving vehicles, falling objects, and high-pressure lines pose a constant threat. Stringent safety protocols and proper equipment maintenance are key to reducing these risks.

Falls are another major concern. Oil rig workers navigate a complex network of platforms and equipment at great heights. A single misstep could lead to a catastrophic fall. Fall protection measures like harnesses and secure railings are essential in this environment.

Explosions and fires are ever-present threats due to flammable vapors and gases. Ignition sources like static electricity or faulty electrical equipment can trigger disasters. Fire suppression systems are incorporated, but preventing ignition is paramount.

Confined spaces like storage tanks and wellhead compartments pose risks of asphyxiation and flammable gas exposure. Workers entering these areas must follow strict safety protocols involving proper ventilation, gas monitoring, and buddy systems.

Ergonomic hazards, such as muscle strain and repetitive stress injuries, are common due to the repetitive nature of tasks and heavy lifting. Proper lifting techniques, ergonomic equipment, and regular breaks can help reduce these risks.

High-pressure lines and equipment pose a significant threat. Leaks or bursts can expose workers to high-pressure blasts, while faulty connections can turn these lines into dangerous projectiles. Regular maintenance and inspections are essential to ensure system integrity.

Unchecked electrical, mechanical, and hydraulic energy sources pose grave dangers. Faulty equipment or improper maintenance can lead to electrical shocks, mechanical entanglement, or uncontrolled energy release. Safeguards and strict operational procedures are crucial for mitigating these risks.

Rotating equipment like drawworks, pumps, and conveyors can cause serious injuries if mishandled. Proper training and maintaining safe distances from unguarded machinery are essential.

Vehicle collisions and flight accidents are additional risks, especially for offshore rigs where helicopter transportation is common. Defensive driving practices, vehicle maintenance, and rigorous pilot training are vital for reducing these risks.

---

Maintaining an oil rig is a meticulous process critical for ensuring safe and efficient operations in the demanding offshore environment.

Regular inspections are the foundation of preventive maintenance. Visual exams of critical equipment, structural assessments, electrical inspections, instrumentation checks, and safety inspections are all part of the regimen. These inspections allow for early identification and mitigation of potential issues.

Scheduled maintenance activities are essential for preventing equipment failures and sustaining optimal performance. Lubrication of moving parts, cleaning and corrosion prevention, component replacement, calibration of instruments, and testing of safety mechanisms are all part of this routine.

Swift and effective action is crucial when issues arise. Detailed troubleshooting helps identify the root cause of malfunctions, minimizing downtime and optimizing repair strategies. Prompt repair or replacement of faulty components restores functionality and prevents further damage.

Efficient spare parts management is crucial for minimizing downtime and optimizing maintenance workflows. Strategic identification and cataloging of critical spare parts, robust supply chain partnerships, secure storage, and continuous inventory optimization are key.

Stringent safety protocols are non-negotiable. Adhering to comprehensive safety procedures, ongoing training, mandatory PPE use, lockout/tagout procedures, and continuous risk assessments are essential for safeguarding personnel, assets, and the environment.

---

Drone inspection offers a safer and faster way to conduct critical inspections on oil and gas rigs. Replacing risky practices like rope access or scaffolding, drones eliminate the need for human inspectors in hazardous areas, significantly reducing accident risks. A 2021 study by the American Petroleum Institute found a 75% decrease in potential fall incidents during offshore rig inspections when drones were used instead of manned crews.

Drones outpace traditional methods, thoroughly inspecting entire rigs in a fraction of the time. Compared to rope access or scaffolding, drone inspections can be completed 5-10 times faster, enabling quicker issue detection and faster corrective actions. This enhances efficiency and shortens turnaround times.

Unlike traditional methods that often require operations to be shut down, drone inspections can be seamlessly conducted while the rig remains fully functional, minimizing production losses and associated costs.

Drone technology isn’t limited to structural inspections. Equipped with high-definition cameras and thermal imaging capabilities, drones act as aerial guardians, detecting security threats and monitoring gas emissions. Multi-gas detectors enable swift leak detection, ensuring compliance with environmental regulations.

Real-time monitoring of oil spills allows for informed decision-making. Early detection and measurement of spills expedite response efforts. Flare stack inspections, traditionally requiring shutdowns and posing risks to personnel, can now be conducted with drones while the stack remains operational.

Advanced software analyzes drone footage, automatically identifying issues and allowing for proactive maintenance before problems escalate. For instance, a drone inspection completed a platform survey in just 10 hours, compared to 30 hours required for manual methods.

Artificial intelligence further enhances inspection efficiency. Machine learning algorithms analyze data collected by drones, identifying defects like coating failures, corrosion, and structural damage. This optimizes maintenance schedules and facilitates proactive intervention to mitigate corrosion-related risks.

---

Contact JOUAV Sales for more information on how drones and AI can revolutionize offshore oil rig inspections!

Milled Parts,Miller Machine Shop,Cnc Machine Shop,Cnc Precision Machining,Precision Machining

Dongguan Changsheng Technology Co., Ltd , https://www.dgcsmachining.com